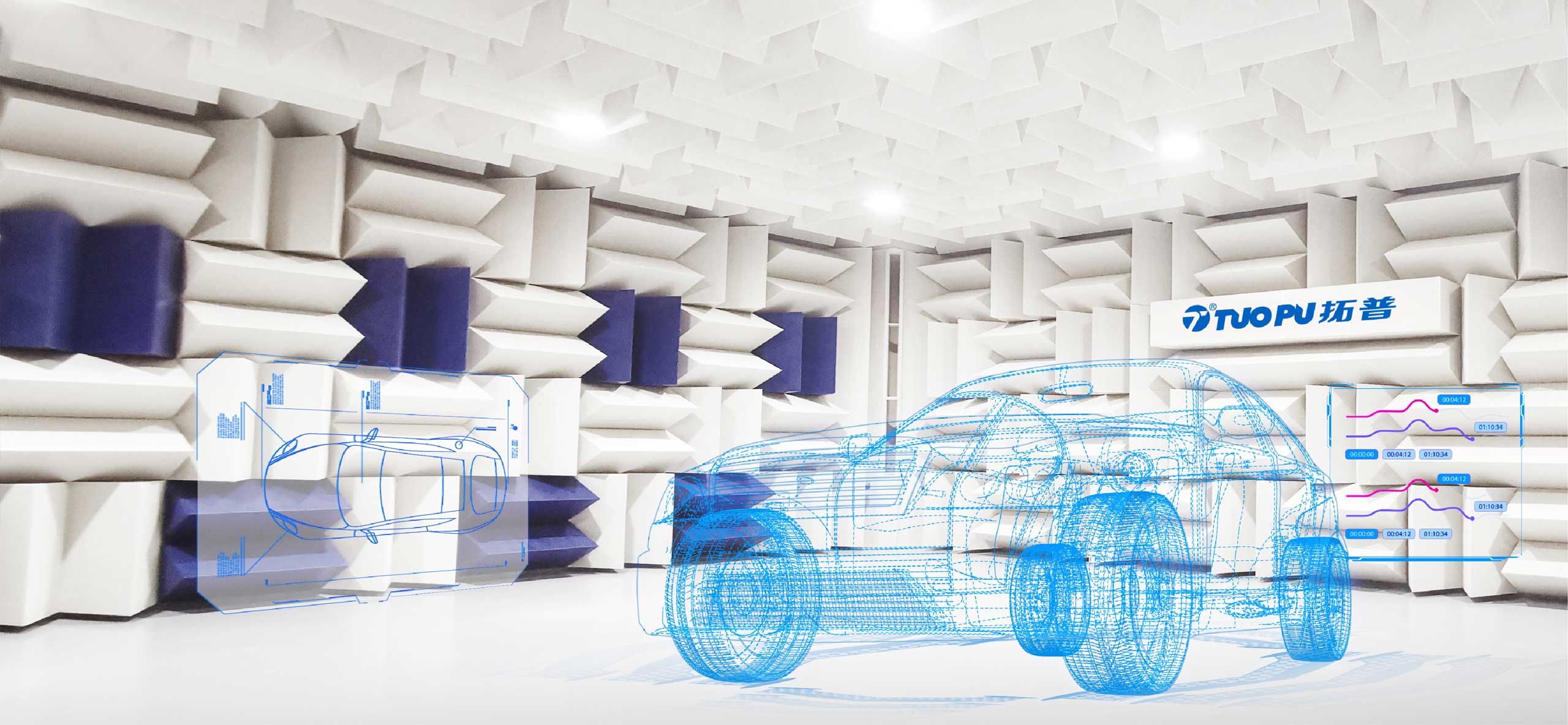

Test Capability

The test center is a specialized facility for testing automotive parts and components, subsystems, and complete vehicles.

The test center is equipped with internationally leading testing equipment and is divided into several testing areas, including structural dynamics, durability and NVH testing area, power chassis product testing area, interior and exterior product testing area, electronic product testing area, and vehicle testing track.

The test center introduced the ISO/IEC:17025 management system in 2005, and passed the certification of laboratory testing capability issued by the China National Accreditation Service (CNAS) for Conformity Assessment in January 2007.Since 2008, the test center has successively obtained laboratory accreditations from major automotive OEMs such as SGM, GEELY, SAIC, BYD, NIO, etc.

Test Categories

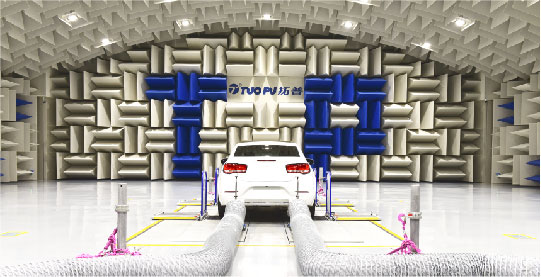

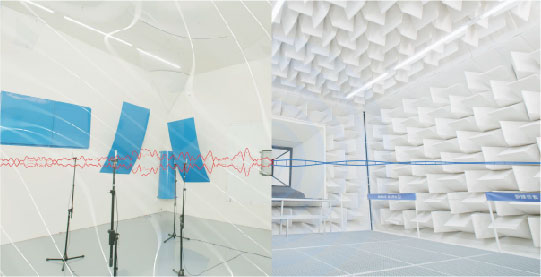

NVH Test

NVH problem optimization and solution of vehicle subsystem and parts

Structural Dynamic Endurance Test

Automotive parts, subsystems, half - body road simulation and dynamic durability verification

Power Chassis Products Test

Automotive shock absorption system, suspension system, chassis system and lightweight structural system products test and verification

Trim Products Test

Focus on the test and verification of soft trim, sealing strip and door plate closing system

Electronic System Part Test

Focus on electronic vacuum pump, motor, intelligent brake, electronic steering system and other products of the test and verification

Proving Ground

Tuopu proving ground occupies a floor area of 15,000 square meters, integrating 10 specially conditioned road sections, acceleration road, low adhesion road, steering test road and hill parking test road for abnormal noise and NVH performance verification of chassis, interiors & exteriors and for whole vehicle performance verification of electronic products.